Production Process

At Pireks, we prioritize high quality and efficiency, applying advanced manufacturing processes to achieve excellent results at every step. With modern technologies and expert teams, we ensure quality at every stage, guaranteeing that each of our products performs at the highest level. Through our continuous development and innovation mindset, we create high-efficiency and reliable production processes, offering solutions tailored to meet every need in the industry.

Raw Materials

Pireks uses high-quality classified scrap materials. Through regular input inspections carried out by our expert teams, we optimize the raw material input to ensure the highest quality in our production process.

Melting

We use induction melting technology in our production processes to achieve clean and high-quality casting. This method enhances energy efficiency while maintaining material purity.

Continuous Casting

With the continuous casting method, we minimize impurities and ensure standard and repeatable production by controlling drawing parameters.

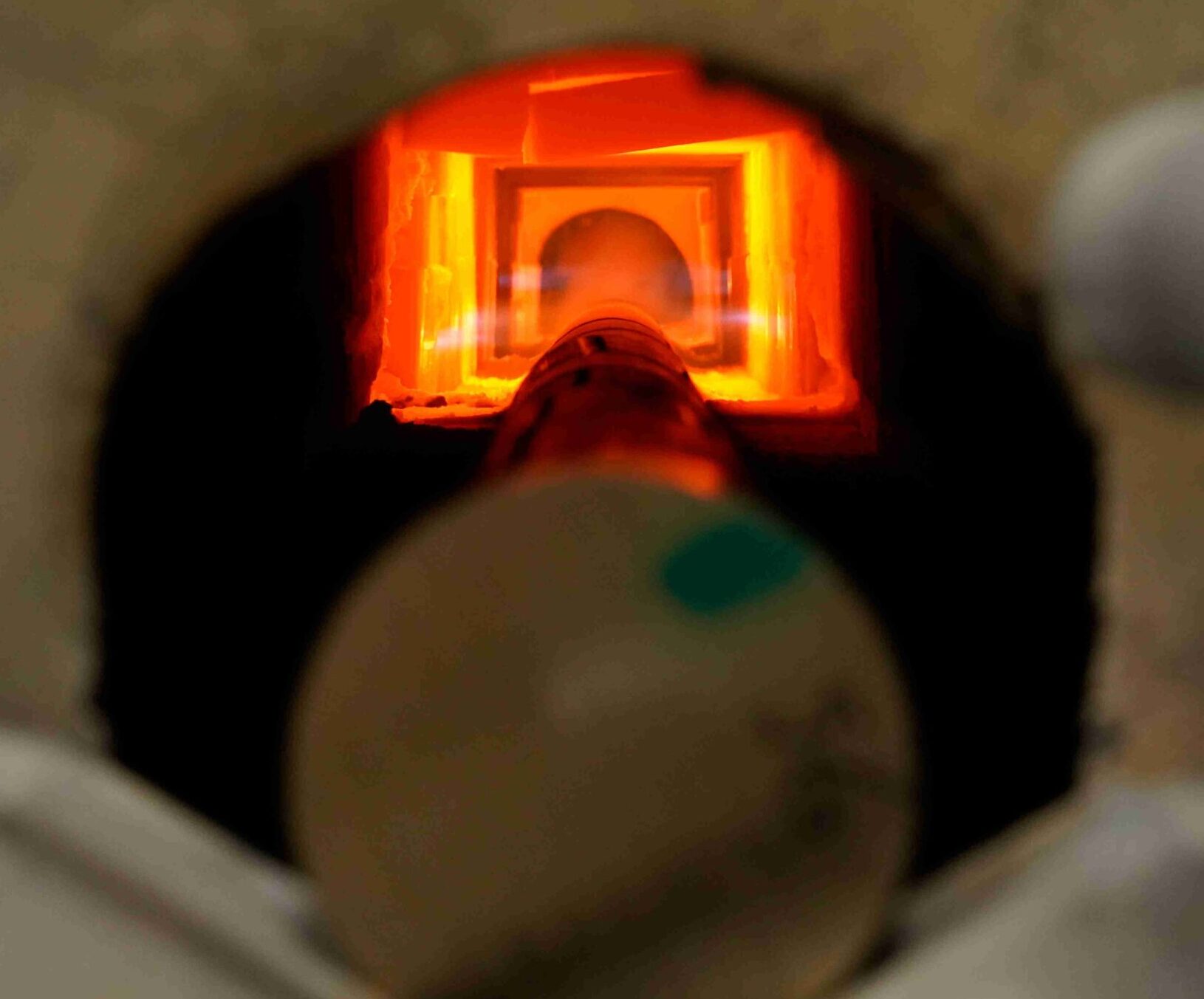

Homogenization

We perform the homogenization process in temperature-controlled natural gas furnaces. This process transforms the brittle and hard structure from casting, making it suitable for the extrusion process.

Extrusion

We produce high-quality products using both direct and indirect extrusion methods. This process allows for mass production in addition to hollow and various profiles. With our mold production infrastructure, production continuity is ensured.

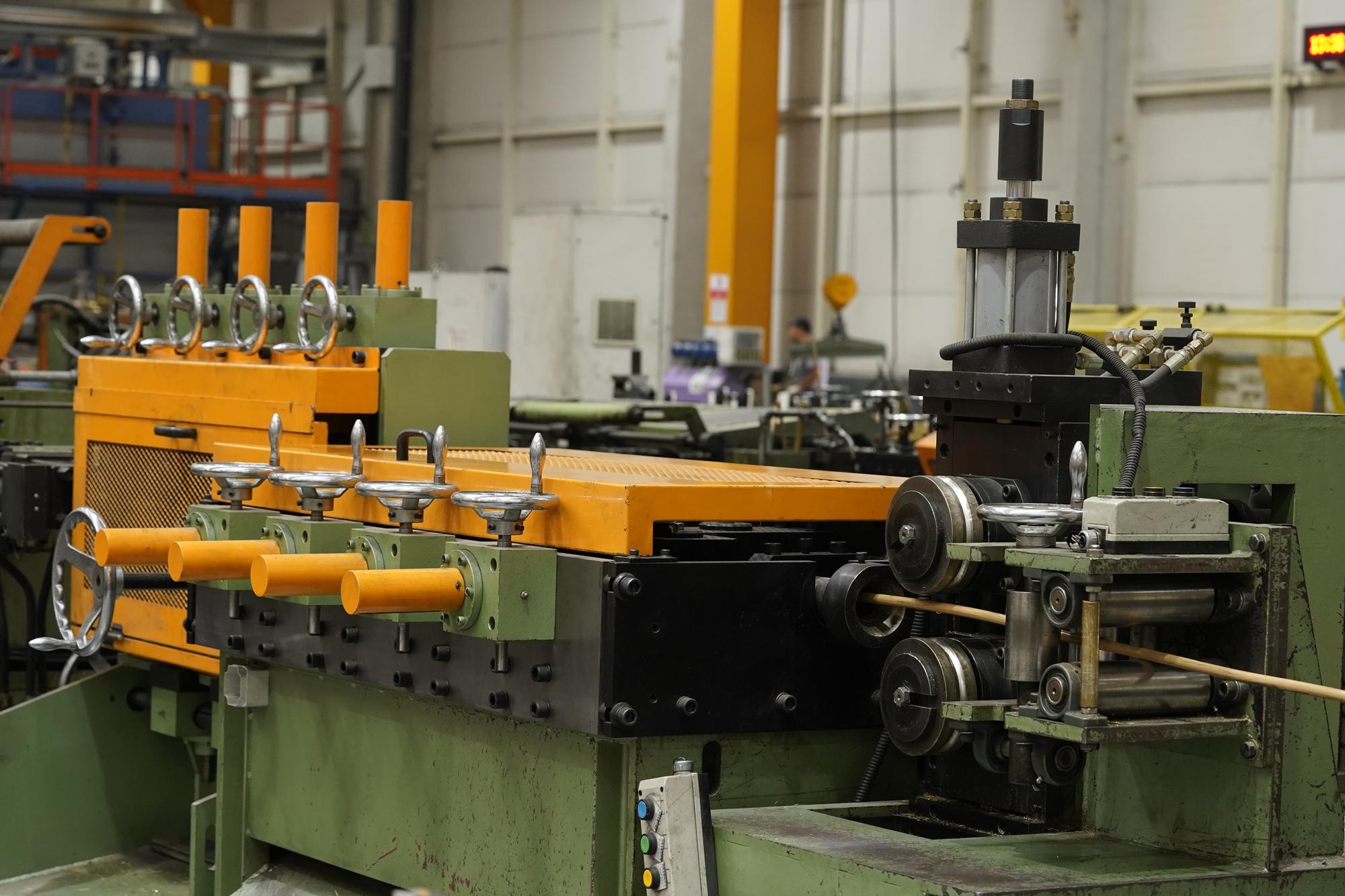

Cold Forming

We produce products with precise tolerances and high machinability using the cold forming method. With our wide production range and machine park, we offer solutions for every sector.

Heat Treatment

We utilize natural gas, electric, and atmosphere-controlled furnaces for all types of heat treatment capabilities, including stress relief, specifically for brass alloys.